Premier Industries, Inc.

INDUSTRIAL EVAPORATIVE PRECOOLER

INTRODUCTION:

The performance of most, if not all air cooled heat

generating equipment decreases inversely

with temperature rise.

A common example of this is the air cooled

condenser coils of air

conditioners. This is illustrated in the following example of a Typical

Trane Chiller Model

RTAC250STD, commonly referred to as a 240 Ton Chiller.

|

Water Temp Out |

AMBIENT TEMPERATURE (F) |

|||||||||||

|

85F |

95F |

105F |

115F |

|||||||||

|

|

TONS |

KW IN |

EER |

TONS |

KW IN |

EER |

TONS |

KW IN |

EER |

TONS |

KW IN |

EER |

|

42F |

244.8 |

247.9 |

10.9 |

229 |

268.5 |

9.5 |

212.7 |

292 |

8.2 |

195.7 |

318.2 |

6.9 |

|

|

||||||||||||

The graph below illustrates this effect.

Following is an illustration of a typical approach to determine the need for precooling. Some equipment cannot meet cooling needs during extremely hot temperatures. Pre-cooling the air is often the simple solution to increase output and reduce operating costs of the equipment and extend the useful lifespan.

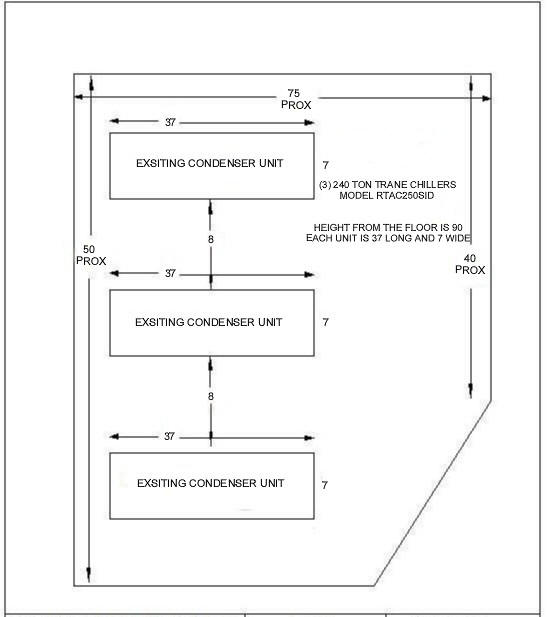

This application involves (3) 250 TON Trane Air Cooled Chillers Model RTAC 250STD installed in a hot dry region, on a ground level concrete slab as shown above.

Equipment Footprint

This

is a plot of the Chillers footprint.

?It

is to be noted that space is a serious consideration.

?Piping

location is another problem.

?Precooling

system selection is limited.

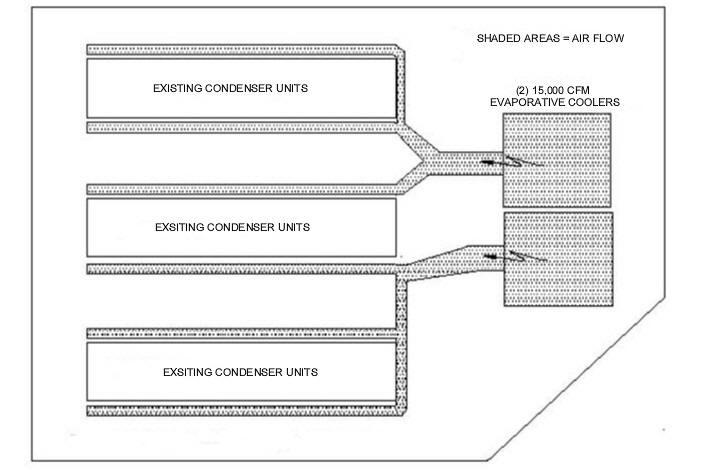

Powered Evaporative

Cooler Layout

Pre-cooling Performance Comparison

|

PERFORMANCE WITHOUT PRECOOLING |

PERFORMANCE WITH PRECOOLING

|

PERFORMANCE IMPROVEMENT WITH PRECOOL |

|||||||

|

TEMP (F) |

TONS |

KWH |

EER |

AMB TEMP |

TONS |

KWH |

EER |

TONS |

KWH |

|

85 |

244.8 |

247.9 |

10.9 |

85 |

249.8 |

242.9 |

11.2 |

5 |

-4.96 |

|

95 |

229 |

268.5 |

9.5 |

95 |

249.8 |

242.9 |

11.2 |

20.8 |

-25.6 |

|

105 |

212.7 |

292 |

8.2 |

105 |

249.8 |

242.9 |

11.2 |

37.1 |

-49.1 |

|

115 |

195.7 |

318.2 |

6.9 |

115 |

249.8 |

242.9 |

11.2 |

54.1

|

-75.3 |

|

NOTE: PRECOOLER DISCHARGE TEMP IS LESS THAN 80F @ 115F AMB TEMP.BASED ON LAS VEGAS, NV., CLIMATE DATA. |

|||||||||

Estimated Energy Cost Savings

|

ESTIMATED KW COST SAVINGS WITH PRECOOLING |

|||

|

AMB TEMP |

KWH SAVINGS |

AVAIL HOURS |

ANNUAL SAVINGS |

|

85 TO 95 |

$.55 |

737 |

$947.33 |

|

95 TO 105 |

$2.82 |

721 |

$2030.34 |

|

105 TO 115 |

$5.40 |

166 |

$896.57 |

|

115 + |

$8.28 |

100 |

$828.30 |

|

|

TOTAL I CHILLER |

2724 |

$4702.53 |

|

|

TOTAL 3 CHILLERS |

3 UNITS |

$14,107.58 |

|

NOTE 1. KWH COST IS

BASED ON $.11/KWH. AVAILABLE HOURS FOR EVAPORATIVE COOLING IS

BASED ON WEATHER DATA HANDBOOK USING A 3 YEAR RUNNING AVERAGE MEASURED

AT NELLIS AFB AT 50' ABOVE GROUND. IT IS TO BE NOTED THAT THE

ACTUAL GROUND TEMPERATURE IN DIRECT SUNLIGHT IS MUCH HIGHER. |

|||